Quality Assurance

Our quality assurance in production includes:

- Incoming goods inspection and MFR/MVR testing of plastics:

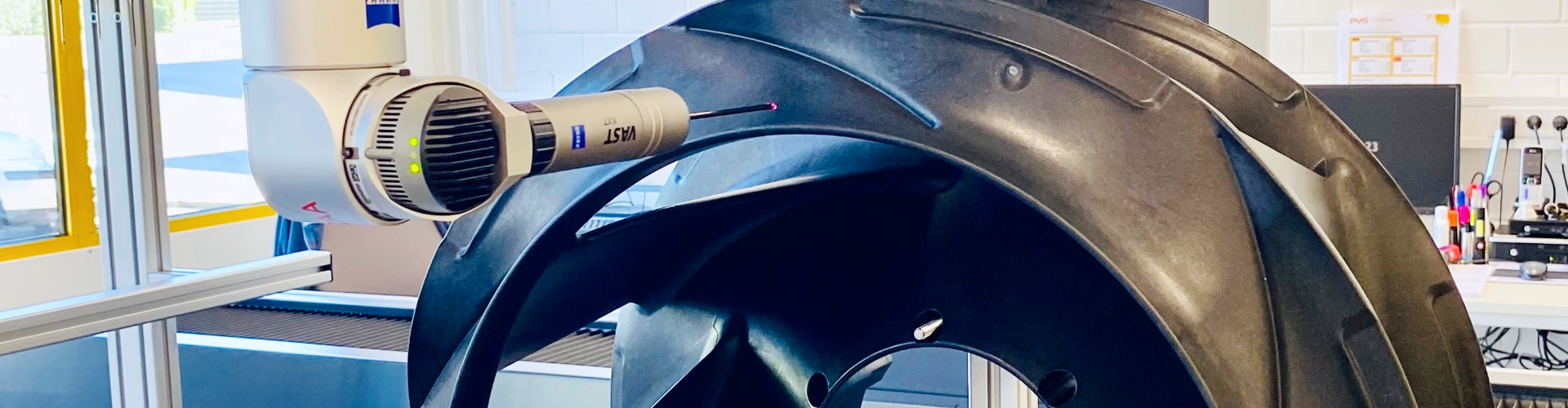

Careful inspection of all incoming materials and testing of the melt flow rate (MFR) and melt volume rate (MVR) of plastics to ensure the highest quality. - Tactile and non-contact measurement technology:

Use of the latest measuring equipment from Zeis for precise, non-contact and tactile measurements. - CAQ-System:

Integrated Computer-Aided Quality System to manage and improve quality assurance processes. - 10 Balancing machines::

State-of-the-art balancing machines to ensure the perfect balance and functionality of our products. - High-voltage testers:

Reliable test equipment for high-voltage testing to ensure electrical safety.

Quality Management

Quality management is more than just a catchword for us:

- Compliance with all normative requirements and customer specifications:

We set the highest standards to meet all legal and customer-specific requirements. - Active QM system:

Our quality management system is actively practiced. Process managers work continuously to optimize all processes and ensure the highest quality. - Use of IT for process and document control:

By using modern IT solutions, we support the efficient control and documentation of our processes. - Internal monitoring system:

As part of our annual audit program, we conduct regular internal reviews to maintain and continuously improve our standards. - Q-Max program for suggestions for improvement:

With our Q-Max program, we actively encourage the submission of suggestions for improvement by our employees in order to continuously improve our processes.